When it comes to keeping a lift station safe, reliable, and easy to maintain, one of the most important components is often overlooked: the guide rail system. While pumps, controls, and floats get most of the attention, guide rails quietly make servicing submersible pumps much easier and safer.

What Are Guide Rails?

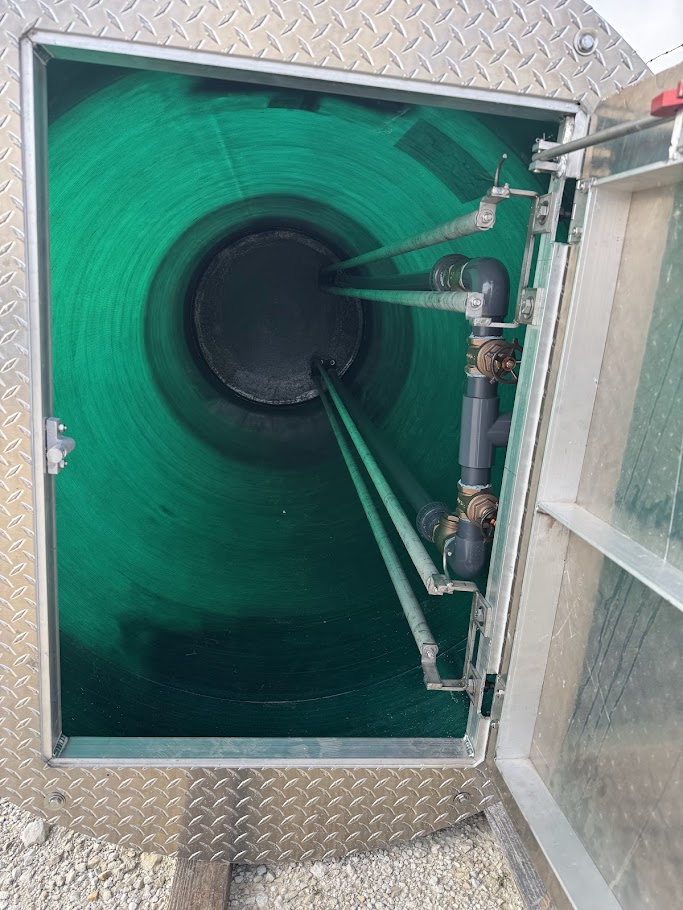

Guide rails are vertical pipes or rails installed inside a wet well that connect to a discharge elbow at the bottom. Submersible pumps are mounted on a slide bracket that attaches to the guide rails. This design allows the pump to be lowered into or lifted out of the wet well without workers needing to enter the confined space.

In simple terms, guide rails let pumps slide into place at the discharge connection, creating a secure and watertight seal without bolts or manual adjustments.

Why Are Guide Rails Important in a Lift Station?

- Safe Maintenance

- Lift stations are considered confined spaces and can contain harmful gases, making entry dangerous.

- Guide rails allow operators to remove pumps from above ground using a lifting chain or hoist, eliminating the need to climb into the wet well.

- Quick Pump Removal and Installation

- With guide rails, pumps can be removed for inspection, cleaning, or repair in a matter of minutes.

- Once serviced, the pump can be lowered back down and automatically reseats at the discharge elbow—no tools required.

- Cost Savings

- Faster pump removal reduces labor time.

- Less downtime for maintenance means the lift station continues operating efficiently with minimal interruption.

- Durability and Alignment

- Guide rails keep the pump securely aligned with the discharge connection.

- This prevents leaks, vibration, and misalignment issues that can damage equipment or reduce performance.

- Standard in Modern Lift Stations

- Most modern municipal and commercial lift stations are designed with guide rails as standard equipment because of their proven safety and efficiency benefits.

Materials and Design

Guide rails are typically constructed from stainless steel or galvanized steel for corrosion resistance in harsh wastewater environments. The discharge elbow is usually cast iron or ductile iron for strength and durability.

Most systems use two guide rails for stability, though smaller pumps may use a single-rail system.

Guide rails may not be the most visible part of a lift station, but they play a critical role in safety, efficiency, and reliability. By eliminating the need to enter a wet well for pump maintenance, they protect workers, reduce downtime, and keep lift stations running smoothly. At Triple D Pump, we provide complete lift station packages—including pumps, guide rails, and controls—designed for long-term performance and easy maintenance.

Give us a call today or request a quote for your custom lift station.