Wastewater pump systems are essential to the functionality of municipal, commercial, and industrial infrastructure. But even well-funded projects can run into major issues when pump system design is rushed or based on outdated assumptions.

At Triple D Pump, we’ve seen firsthand how small design oversights can turn into costly failures down the line. Here are the top five mistakes we regularly encounter—and how you can avoid them.

1. Undersizing or Oversizing the Pump

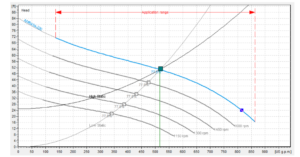

Choosing the wrong pump size is one of the most frequent design pitfalls. Undersizing leads to excessive wear and reduced lifespan, while oversizing can result in cycling issues, energy waste, and higher installation costs.

The fix: Conduct a detailed flow analysis before specifying equipment. Our team helps calculate real-world flow rates and head pressures to ensure optimal sizing for both normal and peak conditions.

2. Ignoring Solids Handling Requirements

Designing a system without accounting for the type and volume of solids in the wastewater stream can cause chronic clogging, downtime, and premature pump failure.

The fix: Use grinder pumps or non-clog pumps depending on the application. Triple D offers expert guidance on solids-handling options and supplies equipment from proven brands like HCP and HOMA.

3. Overlooking Redundancy and Alarms

Some systems are designed without proper backup pumps or alarm systems, especially in budget-sensitive projects. But one pump failure can cause a full system shutdown or environmental spill—risking fines, damage, and reputation.

The fix: Always build in redundancy. We offer duplex and triplex systems with built-in alarms, float controls, and optional SCADA integration for full monitoring and alerts.

4. Poor Control Panel Integration

If the electrical and mechanical systems aren’t designed to work in sync, the result can be nuisance trips, inefficient cycles, and poor diagnostics when things go wrong.

The fix: Choose a control panel that’s designed for your pump system—not just one pulled off the shelf. Triple D partners with Custom Control Technologies and SJE Rhombus to provide intelligent control panels tailored to your exact system.

5. Lack of Serviceability Planning

A beautifully engineered lift station that’s hard to access or service will end up costing more in the long run. We often see stations with buried valves, non-standard parts, or tight enclosures that make maintenance a headache.

The fix: Design with the end user in mind. Our lift stations and pump kits are built for fast access, easy part replacement, and long-term serviceability—because reliability starts with smart planning.

Work with a Team That Designs for Success

Avoiding these common mistakes starts with choosing the right partner. At Triple D Pump, we provide more than just parts—we offer decades of design experience, reliable products from trusted brands, and hands-on support from concept to install.

Request a Quote or Contact Us to learn how we can help keep your next project running smoothly from day one.