The purpose of a lift station is to receive, store temporarily as needed, and move wastewater and/or stormwater through a collection system.

Submersible pump stations come in sizes: very small, small, medium, and large stations, each with its own design parameters. Submersible system components include the fiberglass basin, the pump-motor, piping, valves, float controls, control panel and access hatch covers. Stainless steel guide rail systems can be useful in the deeper stations. Special submersibles, called grinder pumps, are suitable for pressurized sewage system applications.

The two generic types of lift station designs are wet well and wet well/dry well. The wet well/dry well type uses a wet well or pit to collect wastewater and a companion dry well which contains the pumps, controls, and related equipment.

Submersible wet well lift stations are now the standard in modern applications. These systems use a single wet well instead of two, incorporating a submersible solids-handling pump that operates underwater with a submerged inlet. All components install directly in or adjacent to the wet well.

More and more, submersible solids-handling pumps and grinder pumps are being specified by design engineers. Contractors and facility managers use these pumps in wet well sewage lift stations and industrial sump effluent systems. Both large and small units serve a wide range of applications, including homes, hotels, schools, marine facilities, commercial buildings, industrial plants, and municipal sewage and stormwater systems.

Introduction of Submersible Pumps

Submersible pumps have proven effective since their introduction, refuting those skeptics who originally wondered how an electric pump motor “could run under water.” Originally developed in Europe, they are now used throughout the world to pump clear water, raw water, and wastewater. Millions are in continuous use daily.

The submersible wastewater pump came to the United States about 1955. It became popular in the early 1960s, when a pump release idea was developed to allow the pump to be disconnected easily from the piping and be lifted out of the well for service. Currently this feature is referred to as Guide Rail. Guide rails are used on the deeper stations and are constructed of stainless steel. This ended the dirty and sometimes dangerous task of sending personnel into the station to disconnect and then reconnect the pump.

Sizes of Stations

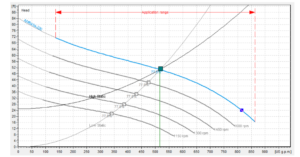

Submersible wastewater pumping stations are usually classified by size in GPM (Gallons Per Minute).

Very Small Stations (less than 80 GPM)

This type of station usually serves an individual dwelling or several isolated buildings. Diameter of the unit is normally 24″ or 36″ with the depth being at least 3′ below the sewage inlet. Simplex pumps may be permitted for private installations; however, duplex units are recommended for service ability. If one pump needs service the other pump is already in place and the utility is not interrupted. Most individual units are package units consisting of a fiberglass basin, pump, piping and controls from one supplier.

Small Stations (80 to 300 GPM)

Duplex stations are specified almost exclusively with each pump sized to handle the peak flow. Provision may be made for future growth by selecting venders who have the same pump models available over a range of impeller or horsepower sizes. Diameter of the unit is normally 48″ and larger to accommodate 2 pumps. It may or may not have guide rails depending on budget and wet well depth. If the unit has guide rails, assembly is offered by most reputable venders thus lowering the cost of on-site installation and labor of the installing contractor. Check valves and gate valves may also be installed inside the wet well in most private applications. In public applications fiberglass valve boxes are available and attached to the wet well.

Medium Stations (300 to 3,000 GPM)

Generally, duplex pump stations are used. The physical size of the wet well itself is based on both the current flow and projected future needs. Depth of the station is partly dictated by the levels of the intake and discharge lines. Diameter is reflective of the pump run time needed and retention time. Guide rails are another option that is commonly used since the pumps are larger/ heavier to lift out. In this size pump station a valve vault or box is normally used and can be attached to the wet well or separate and close to the wet well. The wet well itself may be RCP, but FRP (fiberglass) is more frequently specified.

Large Stations (over 3,000 GPM)

The large wastewater lift station only differs from the medium size in the fact that the pumps are larger horse powers and transport more gallons per minute.