When it comes to wastewater pumps, the impeller is truly the heart of the operation. It’s responsible for creating the flow and pressure that move sewage and solids-laden water through the system. But in wastewater applications, impeller design does much more than that — it determines how efficiently a pump runs, how often it clogs, and how long it lasts.

At Triple D Pump Co., we understand that choosing the right impeller can make all the difference between a reliable, low-maintenance system and one that constantly needs attention. Here’s why impeller design matters — and what to consider when selecting the right one for your lift station or wastewater application.

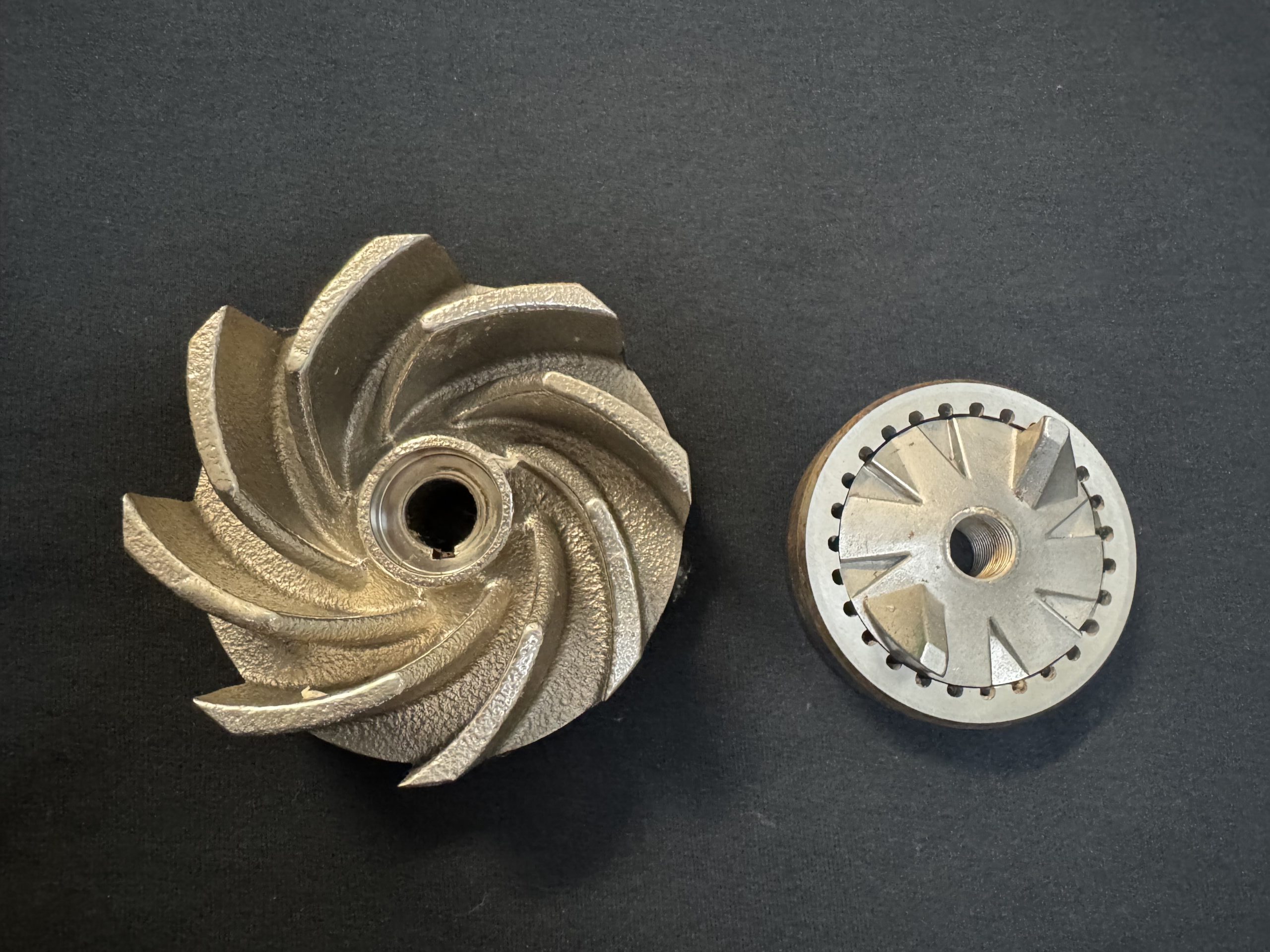

What Is the Impeller?

The impeller is a rotating component inside the pump that transfers energy from the motor to the fluid being moved. As it spins, it draws wastewater in and pushes it outward through the pump casing, creating the pressure necessary to move water through pipes and force mains.

In wastewater environments, however, pumps must do more than just move liquid — they must also handle unpredictable materials like rags, wipes, grease, grit, and other debris. Because of this, the design, shape, and material of the impeller play a crucial role in preventing clogs, maintaining performance, and minimizing wear.

Balancing Efficiency and Solids Handling

Every impeller design involves a trade-off between efficiency and solids-handling capability.

- Single-Vane Impellers:

These are ideal for raw sewage and lift stations where solids are common. With one large flow passage, they handle large debris with minimal clogging but offer slightly lower hydraulic efficiency. - Two-Vane Impellers:

These offer a good balance between efficiency and clog resistance. Two-Vane Impellers are best suited for systems with moderately contaminated wastewater or partially screened flows. - Vortex Impellers:

Instead of making direct contact with solids, vortex impellers create a swirling motion that moves debris through the pump. This makes them highly resistant to clogging — perfect for fibrous or unpredictable waste streams — though they operate at slightly lower efficiency levels. - Cutter and Chopper Impellers:

For systems dealing with heavy solids, wipes, or stringy materials, these impellers actively shred debris as it enters the pump. This reduces clogging and protects downstream components, making them a great option for problem-prone applications.

The Importance of Material Selection

Impeller material is just as important as the design. The right choice depends on the specific environment and the type of wastewater being handled:

- Cast Iron: The industry standard for municipal wastewater systems — durable and cost-effective.

- High-Chrome Iron: Excellent resistance to abrasion in applications where grit or sand is present.

- Stainless Steel or Duplex Steel: Are best for corrosive or industrial wastewater where chemical resistance is required.

Some pumps also include wear rings or protective coatings to extend the lifespan of the impeller and improve performance consistency.

Matching the Right Impeller to the Job

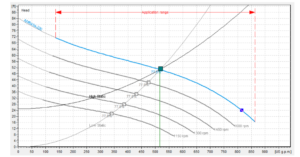

No single impeller design fits every application. Factors such as flow rate, solids content, head requirements, and system design all play a role in selecting the best configuration.

For example:

- A municipal lift station may benefit most from a single-vane impeller for clog-free performance.

- An industrial facility might require a chopper impeller to handle dense or fibrous materials.

- A screened effluent system could run efficiently with a two-vane impeller, optimizing flow and energy use.

Working with experienced pump specialists ensures the right impeller is chosen from the start. Triple D Pump can help you prevent costly maintenance issues and downtime later on.

The impeller may be out of sight, but it should never be out of mind. It determines how well your wastewater pump performs, how efficiently it runs, and how long it lasts. Selecting the right impeller design ensures better reliability, lower energy costs, and fewer maintenance headaches.

At Triple D Pump Co., we help customers choose the right pump and impeller combination for their specific wastewater challenges. Whether you’re building a new lift station or upgrading existing equipment, our team can guide you toward a solution. We strive to balance performance, durability, and long-term value.