When designing or upgrading a wastewater or stormwater system, selecting the right lift station can make or break the long-term performance and cost-efficiency of the project. Whether you’re working on a municipal infrastructure overhaul, a commercial development, or an industrial facility, choosing the correct pump station isn’t just about meeting specs—it’s about ensuring reliability, compliance, and maintainability for years to come.

At Triple D Pump, we’ve supported hundreds of complex projects across the country. Here’s what you need to consider when choosing the right lift station for your job.

1. Understand Your Flow Requirements

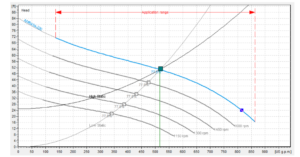

Before choosing any equipment, you need accurate data on average and peak flow rates, head conditions, and solids content. Are you moving raw sewage, stormwater, or a mix? Do you need to handle high volumes with variable flow patterns? Understanding these details early helps determine the size, horsepower, and type of pumps required—whether that’s a non-clog centrifugal pump or a grinder pump.

Pro tip: Oversizing a pump might sound safe, but it can actually reduce efficiency and increase energy costs. We help right-size every station we build.

2. Consider Environmental and Site Constraints

Lift station location matters. Is your site prone to flooding? Are you working in a residential area with strict noise or odor controls? Underground fiberglass stations are a good fit for compact, odor-sensitive locations, while above-ground steel stations may be better for easy maintenance access in industrial zones.

Triple D offers both prefabricated and custom-built lift stations to fit unique site conditions—from tight footprints to aggressive climate zones.

3. Think Long-Term with Maintenance and Access

Large clients often overlook how accessible a station will be for service crews. Lift stations with modular panel design, standardized valves, and quality float controls can save thousands in maintenance over the life of the system.

We build our systems with long-term maintenance in mind—because we know serviceability isn’t optional, it’s critical.

4. Look at Control Panel Integration and SCADA Compatibility

For many municipalities and industrial facilities, remote monitoring is no longer a luxury—it’s essential. The right control panel should integrate seamlessly with SCADA systems, alert operators to faults, and minimize downtime through smart automation.

Triple D Pump partners with trusted control panel manufacturers to offer fully integrated electrical packages, tested and ready to deploy.

5. Choose a Partner—Not Just a Product

A lift station isn’t an off-the-shelf component—it’s a critical part of your infrastructure. That’s why large-scale projects need a supplier who offers engineering support, brand flexibility, and follow-through. At Triple D, we don’t just ship boxes. We collaborate, we problem-solve, and we stay involved long after the station is installed.

Ready to Start Your Lift Station Project?

Whether you’re at the planning stage or need an expert to review your specs, Triple D Pump is here to help. We offer custom-designed lift stations, pump kits, and complete system packages trusted by municipalities, utilities, and commercial developers nationwide.

Contact us today to talk with a technical specialist or request a quote.