Why Cutting Corners Can Cost You More in the Long Run

When it comes to lift stations, the pump is the heart of the system. Choosing the wrong pump for your application can lead to much more than a simple replacement bill—it can result in ongoing maintenance headaches, unexpected downtime, and thousands of dollars in hidden costs.

At Triple D Pump, we’ve seen firsthand how costly a mismatched pump can be. Here’s what you need to know before making that critical selection.

1. Increased Maintenance and Repairs

A pump that isn’t properly matched to the flow rate, head pressure, or waste type will wear out faster. This can lead to:

- Frequent seal and bearing replacements

- Impeller damage from improper handling of solids

- Motor overloads from operating outside the recommended range

While repairs may seem minor at first, repeated service calls add up quickly.

2. Reduced Lifespan

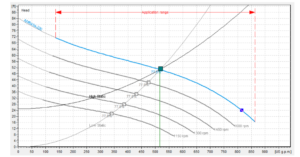

Pumps are designed to operate in a specific Best Efficiency Point (BEP). Running too far outside this range puts extra stress on the pump and motor, dramatically reducing lifespan. A pump that should last 15 years may fail in just 3–5 years if it’s the wrong size or type for the job.

3. Higher Energy Bills

An oversized pump wastes energy by running harder than necessary, while an undersized pump may need to run longer to keep up—both scenarios increase electrical costs. Over years of operation, inefficient pumping can cost tens of thousands of dollars in extra power usage.

4. Downtime and Emergency Costs

When the wrong pump fails unexpectedly, you may face:

- Emergency service call fees

- Rental pump costs while yours is repaired

- Potential sewer overflows or environmental fines

- Loss of public trust in municipal or commercial systems

These downtime costs can far outweigh the savings from choosing a cheaper or incorrectly specified pump upfront.

5. Mismatched Pump Types Cause Problems

Not all pumps are created equal:

- Grinder pumps are ideal for handling solids in low-flow applications.

- Cutter pumps are designed to chop and move fibrous materials.

- Non-clog pumps excel in higher-flow systems with large solids.

Using the wrong type can lead to clogging, ragging, or even motor burnout—issues that could have been avoided with the right selection. We go into more detail about the differences in pump types here.

How to Avoid the Wrong Pump

- Get a professional site assessment – Evaluate flow rates, head pressure, and waste type before making a purchase.

- Match the pump to your application – Choose the right type, size, and material for your specific conditions.

- Work with experienced pump specialists – At Triple D, we’ve designed and installed pumps for thousands of lift stations, so we know what works and what doesn’t.

Triple D Pump: Your Partner in Pump Selection

The cheapest pump up front is rarely the cheapest pump over time. At Triple D Pump, we help municipalities, developers, and contractors select the right pump the first time, saving money, reducing downtime, and keeping systems running for decades.

Planning a new facility or replacing a pump? We can design your pump system right. And yes—we offer FREE quotes to make the decision easier.