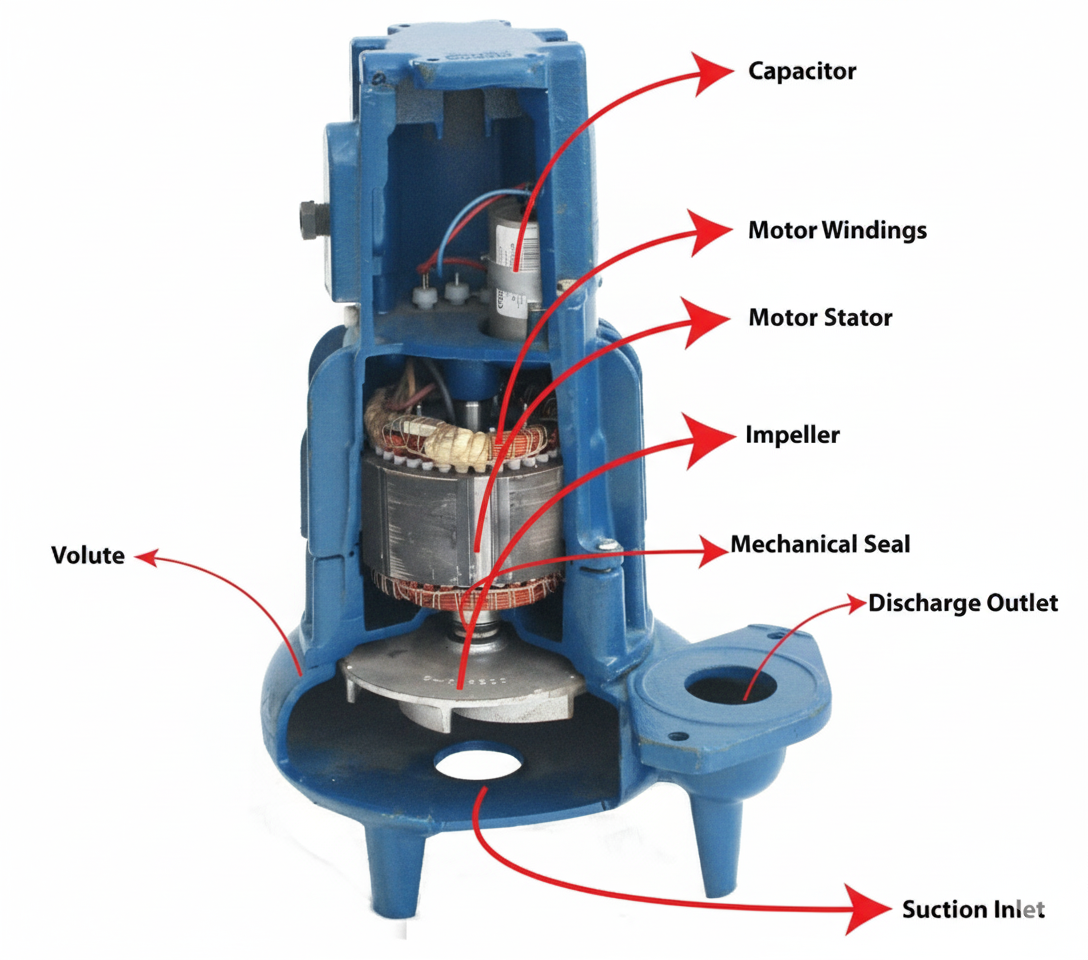

Submersible pumps are widely used in wastewater, industrial, agricultural, and municipal applications because they can operate while completely submerged in liquid. Their design eliminates priming issues, reduces noise, and often provides higher efficiency compared to other pump types. To properly install, maintain, or troubleshoot these pumps, it’s essential to understand their main components and the role each plays in reliable operation.

1. Pump Casing (Volute or Bowl Assembly)

The casing forms the outer shell of the pump and contains the liquid being moved. It directs fluid flow efficiently toward the discharge outlet while protecting the internal components. In wastewater pumps, the casing is designed to handle solids and prevent clogging.

2. Impeller

The impeller is the rotating component that transfers energy from the motor to the fluid. As it spins, it accelerates liquid outward, creating flow and pressure. Impellers may be:

- Open or semi-open: Better for handling solids and stringy materials.

- Closed: More efficient in clean-water applications.

3. Pump Shaft

The shaft connects the impeller to the motor and transmits rotational energy. Shafts are typically made of stainless steel or other corrosion-resistant alloys to withstand harsh environments. A straight, well-balanced shaft is crucial for minimizing vibration and wear.

4. Bearings

Bearings support the shaft, allowing smooth rotation with minimal friction. Submersible pumps may use grease-lubricated, oil-lubricated, or permanently sealed bearings. Proper bearing function is critical to avoid overheating and mechanical failure.

5. Mechanical Seal

The mechanical seal prevents liquid from leaking into the motor section of the pump. It consists of two precision-machined surfaces—one rotating with the shaft, the other stationary. In wastewater applications, double mechanical seals (with an oil chamber in between) are commonly used for added protection.

6. Motor

The motor is housed in a watertight chamber to keep electrical components isolated from the pumped liquid. Submersible pump motors are typically squirrel-cage induction motors, designed for continuous or intermittent duty. Some pumps include built-in thermal protection to prevent overheating.

7. Power Cable and Cable Entry

Power cables deliver electricity to the motor. A reliable cable entry system is critical, as water intrusion through damaged or poorly sealed cables is one of the most common causes of pump failure. High-quality pumps use molded cable entries or compression grommets for secure sealing.

8. Cooling System

In some designs, the pumped fluid cools the motor as it passes around the motor housing. Others use a dedicated cooling jacket filled with fluid to dissipate heat. Proper cooling ensures motor longevity and efficient operation.

9. Discharge Connection

The discharge outlet directs pumped liquid into the piping system. It is typically located at the side of the casing.

Conclusion

Each component of a submersible pump plays a vital role in overall performance. The impeller and casing handle fluid movement, the shaft, seals, and bearings ensure mechanical stability, and the motor, cables, and protective devices keep the pump operating reliably under demanding conditions. By understanding these parts, operators and maintenance teams can better select, maintain, and troubleshoot submersible pumps, ensuring maximum efficiency and extended service life.

Ready to maximize your pump’s efficiency and lifespan? Explore Triple D Pump’s full range of submersible pumps, parts, and maintenance solutions.