When it comes to designing or troubleshooting a sewer lift station, one term you’ll hear a lot is Total Dynamic Head (TDH). It’s not just industry jargon—TDH is the key measurement that ensures your pumps are sized correctly and your system runs efficiently. If you get it wrong, you could end up with poor performance, higher energy costs, or even premature pump failure.

Let’s break down what TDH means, why it matters, and how to calculate it.

What Is Total Dynamic Head?

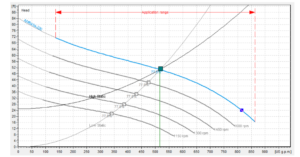

Total Dynamic Head is the total amount of energy (measured in feet of head) that a pump needs to move water from one point to another. It’s essentially the “total resistance” the pump must overcome to move wastewater through your lift station and into the force main.

TDH is made up of three main components:

- Static Head – The vertical distance between the water level in the wet well and the discharge point.

- Friction Loss – The resistance caused by wastewater moving through pipes, valves, and fittings.

- Pressure Head (if applicable) – Any additional pressure the pump must work against, such as entering a pressurized main.

Why TDH Is Important

If you undersize the pump (choose a pump for a TDH that’s too low), it won’t move enough water and could burn out from working too hard. If you oversize it, you might waste electricity, create excessive wear on the system, and cause unnecessary turbulence in your force main.

Correctly calculating TDH ensures:

- Optimal pump efficiency

- Lower operational costs

- Longer pump lifespan

- Reliable system performance

How to Calculate TDH for a Lift Station

Step 1: Measure Static Head

Measure the vertical lift from the “pump on” water level in the wet well to the discharge point of your system. This is your Static Head in feet.

Step 2: Calculate Friction Loss

Friction loss depends on:

- Pipe length and diameter

- Number of fittings (elbows, tees, valves)

- Flow rate (in gallons per minute)

You can find friction loss values from pipe manufacturer charts or pump engineering references. Add up the losses for all components in the system.

Step 3: Add Any Pressure Head

If your lift station discharges into a pressurized line, convert the pressure into feet of head (1 PSI ≈ 2.31 feet of head) and add it to the total.

Step 4: Combine the Numbers

TDH=Static Head + Friction Loss + Pressure Head

Example:

- Static Head: 20 ft

- Friction Loss: 10 ft

- Pressure Head: 5 ft

TDH=20+10+5=35

This means you’d select a pump designed to operate efficiently at 35 feet of head for your required flow rate.

Triple D Pump Can Help

At Triple D Pump Company, we’ve been calculating TDH and sizing pumps correctly for decades. Whether you’re installing a new lift station or replacing a pump, we’ll make sure your system has the right pump for the job—saving you time, money, and headaches.

Give us a call at 254-772-7623, and we will be happy to answer your questions, or fill out the form below to request a sewer lift station cost estimate.